Homodyne detection: Difference between revisions

Johnkhootf (talk | contribs) →Results & Discussion: Discuss issues with EOM board and crystal reflections |

Johnkhootf (talk | contribs) →Setup & Methodology: Add tragic LiNbO3 story and explain choice of bases |

||

| Line 72: | Line 72: | ||

=== Mounting and Wiring Components === | === Mounting and Wiring Components === | ||

In order to provide a consistent voltage throughout, and to avoid the hassle of changing batteries when they are depleted, it is advantageous to power devices using benchtop power supplies instead of batteries, whose output voltage will vary over the course of the experiment. We converted a laser pointer, powered by 3 1.5V batteries in series, and a photodiode, powered by a 9V battery, to do so. | In order to provide a consistent voltage throughout, and to avoid the hassle of changing batteries when they are depleted, it is advantageous to power devices using benchtop power supplies instead of batteries, whose output voltage will vary over the course of the experiment. We converted a laser pointer, powered by 3 1.5V batteries in series, and a photodiode, powered by a 9V battery, to do so. | ||

| Line 90: | Line 89: | ||

=== Laser & Beam Splitter Alignment === | === Laser & Beam Splitter Alignment === | ||

As discussed in the theory section, we would obtain the most visible fringes if all mirrors to be at right angles to each other, the beam splitter's faces, and the plane of observation. Therefore, we use the grid of the optical table to align these elements. Due to the improvised construction of the laser, it is not perfectly aligned to the centre of its post. Its aperture is also much smaller than the grid spacing. Similarly, the beam splitter was attached to its post using double-sided tape, and is smaller than the grid spacing. Therefore, we mounted these elements on two-slot bases, allowing their posts to be easily translated between two grid holes to achieve the ideal alignment. | |||

TODO alignment process | |||

=== Mirror Alignment === | === Mirror Alignment === | ||

Since the mirrors are planes of diameter comparable to the grid spacing, and we only need to ensure the beams are incident on the plane, we are able to use the smaller one-slot bases for the mirrors, TODO explain. This also helps to ensure that the paths are approximately the same length, so that the two arms remain coherent with each other. | |||

TODO pictures of alignment | |||

=== The EOM Board === | === The EOM Board === | ||

TODO | The EOM board consists of a coaxial socket, a capacitor, and the <chem>LiNbO3</chem> crystal itself. The top surface of the crystal is connected to a copper plate, while the bottom surface is connected to a pad on the board, and both are connected to different terminals of the coaxial socket. | ||

TODO image of board | |||

The effective circuit is as follows: | |||

TODO circuit diagram | |||

The effective impedance of this circuit is given by | |||

<math> | |||

\begin{align} | |||

Z_{\mathrm{eff}} &= {\left(\frac{1}{Z_{\mathrm{EOM}} + R_{\mathrm{EOM}}} + \frac{1}{Z_C + Z_L + R}\right)}^{-1} \\ | |||

&= \frac{\left(C_{\mathrm{EOM}} R_{\mathrm{EOM}} \omega - i\right) \left(C L \omega^{2} - i C R \omega - 1\right)}{\omega \left[C C_{\mathrm{EOM}} \left( L \omega^{2} - i (R + R_{\mathrm{eff}}) \omega \right) - C - C_{\mathrm{EOM}}\right]} | |||

\end{align} | |||

</math> | |||

The <chem>LiNbO3</chem> crystal acts as a capacitor. The top and bottom surfaces of the crystal are coated in gold to ensure a uniform electric field throughout the crystal. Considering the crystal as a parallel plate capacitor, any gaps between the crystal and the "conducting plates" would change the capacitance over those gaps, resulting in an uneven electric field and therefore an uneven phase shift for different parts of the beam, reducing visibility. | |||

TODO check solvent in silver epoxy | |||

However, the crystal had been disconnected from the board by previous users. The connections between the crystal, plate, and board were all made using silver epoxy, which consists of conductive silver dissolved in an organic solvent at room temperature. The advantage of silver epoxy over solder is that we can avoid subjecting the crystal to heat stress from a soldering iron, which may cause it to fracture. It was therefore necessary to reattach the crystal to the board using silver epoxy. | |||

The attempt to repair the EOM board was fraught with misadventures and consumed a significant amount of time. In brief summary: | |||

# The only silver epoxy we found expired 5 years ago and had dried up into solid lumps. We were able to dissolve the dried epoxy using organic solvents and attempt to reapply it to the crystal, but this was a messy affair and the joints formed were not mechanically stable (or at least, not stable enough to survive the various mishaps that occurred after the joints were formed, such as the board being dropped, or other adjustments being made to the board subjecting the joints to too much stress) | |||

# A new replacement epoxy was eventually procured, which, in comic contrast to the solidified old epoxy, was too liquid. Attempts to hasten the binding process using hot air to evaporate the solvent did not succeed, and the liquid epoxy was even more messy. The ultimate solution was to leave the solvent in place with a weight pressing down on it, and to let it slowly evaporate. | |||

# In another ironic twist, after finally fixing the crystal to the board after one month of effort, an adjustment being made to the wire connected to the top plate caused the plate to break off from the crystal. Fortunately, we had learnt our lesson from previous attempts to fix the crystal to the board, and the plate was reattached promptly using the epoxy (although we still had to wait a few days for the solvent to evaporate). | |||

# The messiness of the epoxy was not merely cosmetic: it occluded the optical surfaces of the crystal and formed short circuits between the top and bottom plates. Fortunately, the epoxy does not adhere very strongly to the board or the crystal (adhering instead to metallic surfaces like the gold paint and the solder pads on the board), and was able to be scraped off places where it did not belong. | |||

The repair of the board was not the end of our troubles. It is also difficult to align properly, because the solder mounds on the underside of the board make it difficult to seat the board firmly on the optical mount, while the tension in the coaxial cable used to supply the voltage also makes the system very unstable. Initial attempts to fix the position of the board by pressing it down with a wedge met some success, but it was still too prone to being misaligned while the setup was being adjusted. | |||

TODO picture of wedge | |||

Fortunately, the holes in the board are, by coincidence, mostly aligned with the holes in the mount. Although the mount uses imperial-sized screws, we were able to find the screws and components necessary to fix the board in place securely, producing the rather ugly assemblage pictured below. | Fortunately, the holes in the board are, by coincidence, mostly aligned with the holes in the mount. Although the mount uses imperial-sized screws, we were able to find the screws and components necessary to fix the board in place securely, producing the rather ugly assemblage pictured below. | ||

| Line 103: | Line 138: | ||

TODO insert picture | TODO insert picture | ||

We | We also elected to place the board on a mount permitting the pitch and roll of the board to be adjusted, because it is difficult to guarantee its alignment otherwise, and since the crystal is birefringent, we want to ensure it is aligned with the polarisation of the laser, so that the whole beam will experience the same phase difference, and the fringe visibility can be maximised. | ||

=== Lens and Photodiode Alignment === | === Lens and Photodiode Alignment === | ||

Revision as of 04:56, 27 April 2022

Introduction

Optical homodyne detection is a method for detecting messages transmitted in optical signals, where a frequency or phase modulated signal is compared to what is misleadingly called the "local oscillator" (LO) signal, which is generated from the same source but not modulated with the message. In order to probe quantum effects, it is important to bring the noise of the detector down to the shot-noise limit, where the only fluctuations observed arise from the discrete nature of photons, which can be theoretically modelled as the vacuum-state fluctuations of the quantised electromagnetic field. This project's first objective is to build a homodyne detector from scratch.

Lab Location: S11-02-04 (Optics Lab)

Application: Continuous-variable QKD with Gaussian modulation and coherent states

While the first protocols for quantum key distribution (QKD) involved discrete variables (DV) in finite, small dimensions, QKD can also be done using continuous variables (CV) in infinite dimensions, i.e. the state of an electromagnetic field. Using Gaussian modulation and coherent states makes the QKD system relatively easy to implement and analyse, although getting positive key rates is a different matter. The homodyne detector is an essential component of this setup, but if we have the capacity, we can try to develop other parts of the system, such as the implementation of the QKD protocol itself in software. We want to pay particular attention to the design of the amplifier for the homodyne detector, for which there are stringent requirements and difficult tradeoffs to make.

Reality

What we actually ended up working towards is a simple version of the system proposed above. Instead of building a system capable of sending useful information, we aimed for the simpler objective of just being able to produce some kind of phase modulation. This is a stepping stone towards a full-blown optical communication system, where digital data is modulated onto the laser by a computer and read off from the results of the homodyne detection.

Background Reading

Our primary source of background information is Lasers and Electro-Optics, available for download via NUS Library. The relevant chapters are:

- Chapter 5 Laser Radiation, discussing the basic background on lasers

- Chapter 18 The Electro-optic and Acousto-optic Effects and Modulation of Light Beams, discussing how modulation can be achieved

- Chapter 21 Detection of Optical Radiation, discusses noise in detectors and the process of homodyne detection

For DV-QKD theorists who stumbled into this (like me), here's some background reading on CV-QKD:

- Review of Gaussian quantum-information processing

- Self-contained tutorial on theory of Gaussian-modulated CV-QKD

Tragically, we were nowhere close to being able to use the material on CV-QKD, but we leave the references here for posterity.

Theory

The Michelson Interferometer

Gaussian Beams

Misaligned Mirrors

Phase Modulation

The next question is how to vary in an easily controllable manner. TODO

Talk about LiNbO3 structure, birefringence, electro-optic effect

Noise

Finally, we have to control for the effect of noise in our experiment. There are four primary sources of noise in semiconductor photodetectors:

- Shot noise, or quantum noise, arising from the quantisation of light: because the light must arrive at the detector one photon at a time, there will be some fluctuation in the signal read at any point in time.

- Nyquist-Johnson noise or thermal noise, arising from thermal fluctuations in the electronics.

- noise, which is apparently a very mysterious and universal phenomenon caused by various different factors, but has a power spectral density proportional to , hence the name.

- Generation-recombination (GR) noise, caused by holes and electrons randomly being generated and recombining in the semiconductor.

is the sampling bandwidth, related to how often we take electrical measurements. By Nyquist's theorem, we must have a sampling period Failed to parse (Conversion error. Server ("https://wikimedia.org/api/rest_") reported: "Cannot get mml. Server problem."): {\displaystyle T=1/\Delta f\leq 1/2f} to reconstruct a modulated signal of maximum frequency component Failed to parse (Conversion error. Server ("https://wikimedia.org/api/rest_") reported: "Cannot get mml. Server problem."): {\displaystyle f} : that is, we must have Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle \Delta f \geq 2f} .

Setup & Methodology

Homodyne Detection Setup

The overview for the initially intended experiment is:

- Split the laser beam into two, one component will be LO and another will be the signal

- Frequency-shift the signal beam using an acousto-optical modulator (AOM)

- Phase-modulate the signal beam using an electro-optical modulator (EOM). This is typically a Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle \ce{LiNbO3}} crystal, whose birefringence is controlled by the voltage applied to it. For more advanced applications, we can use a transformer to amplify a small change in voltage into a large difference, producing a large change in the birefringence.

- Recombine the signal and the LO in a 50:50 beam splitter

- Send the two output beams to two reverse-biased photodiodes, and connect the junction between the photodiodes to a current detector to convert it to a voltage. The signal will be modulated according to the beat frequency.

The noise in the photodiodes tends to be low frequency, so aiming for a signal of frequency Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle 10~\mathrm{MHz}} or so will make it easier to remove the noise without affecting the signal.

Actual Setup

As the theory section indicates, we are constructing a Michelson interferometer with a Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle \ce{LiNbO3}} crystal on one arm, serving as a voltage-controlled phase modulator. The voltage across the crystal controls the refractive index, which changes the path difference Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle \delta} and therefore the phase difference. If the fringes are circular, the total intensity on the photodiode will vary significantly as the phase changes. This can be read off by using the photodiode as a current source and measuring the voltage it induces across a resistor.

A high-level overview is as follows:

- Modify and wire up all battery-powered equipment (detectors and laser pointer) to use benchtop power supplies instead, and mount them on optical posts

- Align the laser to ensure it is parallel to the table and its grid

- Align the beam splitter to the grid of the table and the laser

- Align the mirrors to produce circular fringes

- Place and align the crystal so the beam passes through it

- Align the lens to magnify the interference pattern, and align the photodiode so that it coincides with the pattern

Mounting and Wiring Components

In order to provide a consistent voltage throughout, and to avoid the hassle of changing batteries when they are depleted, it is advantageous to power devices using benchtop power supplies instead of batteries, whose output voltage will vary over the course of the experiment. We converted a laser pointer, powered by 3 1.5V batteries in series, and a photodiode, powered by a 9V battery, to do so.

The photodiode was easy to convert, since the terminals of the photodiode were connected to screw terminals. It was a simple matter to open the terminals, remove the wires connected to the battery, and insert new wires that were connected via crocodile clips to a benchtop power supply.

TODO insert photo of converted photodiode

The laser pointer was much more difficult to work with. When using batteries, the negative terminal of the batteries would be connected to the spring inside the laser pointer, while the positive terminal would be in electrical contact with the inside of the body of the laser pointer. A insulating sheath prevents short circuits.

TODO insert labelled photo of inside of laser pointer

To connect the laser pointer to the benchtop power supply, the two contacts had to be replaced with crocodile clips, connected to the benchtop power supply. However, most clips were too large to fit inside the laser pointer body, and those that did fit were very difficult to manipulate due to taking up most of the volume of the body. Additionally, the clips had to be insulated to prevent them from forming a short circuit, since they were placed very close to each other.

The correctly-sized crocodile clips and rubber sleeves were found scattered throughout the lab, and we had to perform a simple improvised crimp to attach wires to the clips. Lastly, we used a pair of cutters to cut the body of the laser pointer to expose the coil within, so the crocodile clips could be attached. We were careful to preserve the insulating sheath, to ensure the circuit could be formed properly.

TODO insert photo of final laser setup

Laser & Beam Splitter Alignment

As discussed in the theory section, we would obtain the most visible fringes if all mirrors to be at right angles to each other, the beam splitter's faces, and the plane of observation. Therefore, we use the grid of the optical table to align these elements. Due to the improvised construction of the laser, it is not perfectly aligned to the centre of its post. Its aperture is also much smaller than the grid spacing. Similarly, the beam splitter was attached to its post using double-sided tape, and is smaller than the grid spacing. Therefore, we mounted these elements on two-slot bases, allowing their posts to be easily translated between two grid holes to achieve the ideal alignment.

TODO alignment process

Mirror Alignment

Since the mirrors are planes of diameter comparable to the grid spacing, and we only need to ensure the beams are incident on the plane, we are able to use the smaller one-slot bases for the mirrors, TODO explain. This also helps to ensure that the paths are approximately the same length, so that the two arms remain coherent with each other.

TODO pictures of alignment

The EOM Board

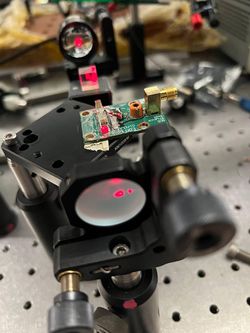

The EOM board consists of a coaxial socket, a capacitor, and the Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle \ce{LiNbO3}} crystal itself. The top surface of the crystal is connected to a copper plate, while the bottom surface is connected to a pad on the board, and both are connected to different terminals of the coaxial socket.

TODO image of board

The effective circuit is as follows: TODO circuit diagram

The effective impedance of this circuit is given by

Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle \begin{align} Z_{\mathrm{eff}} &= {\left(\frac{1}{Z_{\mathrm{EOM}} + R_{\mathrm{EOM}}} + \frac{1}{Z_C + Z_L + R}\right)}^{-1} \\ &= \frac{\left(C_{\mathrm{EOM}} R_{\mathrm{EOM}} \omega - i\right) \left(C L \omega^{2} - i C R \omega - 1\right)}{\omega \left[C C_{\mathrm{EOM}} \left( L \omega^{2} - i (R + R_{\mathrm{eff}}) \omega \right) - C - C_{\mathrm{EOM}}\right]} \end{align} }

The Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle \ce{LiNbO3}} crystal acts as a capacitor. The top and bottom surfaces of the crystal are coated in gold to ensure a uniform electric field throughout the crystal. Considering the crystal as a parallel plate capacitor, any gaps between the crystal and the "conducting plates" would change the capacitance over those gaps, resulting in an uneven electric field and therefore an uneven phase shift for different parts of the beam, reducing visibility.

TODO check solvent in silver epoxy

However, the crystal had been disconnected from the board by previous users. The connections between the crystal, plate, and board were all made using silver epoxy, which consists of conductive silver dissolved in an organic solvent at room temperature. The advantage of silver epoxy over solder is that we can avoid subjecting the crystal to heat stress from a soldering iron, which may cause it to fracture. It was therefore necessary to reattach the crystal to the board using silver epoxy.

The attempt to repair the EOM board was fraught with misadventures and consumed a significant amount of time. In brief summary:

- The only silver epoxy we found expired 5 years ago and had dried up into solid lumps. We were able to dissolve the dried epoxy using organic solvents and attempt to reapply it to the crystal, but this was a messy affair and the joints formed were not mechanically stable (or at least, not stable enough to survive the various mishaps that occurred after the joints were formed, such as the board being dropped, or other adjustments being made to the board subjecting the joints to too much stress)

- A new replacement epoxy was eventually procured, which, in comic contrast to the solidified old epoxy, was too liquid. Attempts to hasten the binding process using hot air to evaporate the solvent did not succeed, and the liquid epoxy was even more messy. The ultimate solution was to leave the solvent in place with a weight pressing down on it, and to let it slowly evaporate.

- In another ironic twist, after finally fixing the crystal to the board after one month of effort, an adjustment being made to the wire connected to the top plate caused the plate to break off from the crystal. Fortunately, we had learnt our lesson from previous attempts to fix the crystal to the board, and the plate was reattached promptly using the epoxy (although we still had to wait a few days for the solvent to evaporate).

- The messiness of the epoxy was not merely cosmetic: it occluded the optical surfaces of the crystal and formed short circuits between the top and bottom plates. Fortunately, the epoxy does not adhere very strongly to the board or the crystal (adhering instead to metallic surfaces like the gold paint and the solder pads on the board), and was able to be scraped off places where it did not belong.

The repair of the board was not the end of our troubles. It is also difficult to align properly, because the solder mounds on the underside of the board make it difficult to seat the board firmly on the optical mount, while the tension in the coaxial cable used to supply the voltage also makes the system very unstable. Initial attempts to fix the position of the board by pressing it down with a wedge met some success, but it was still too prone to being misaligned while the setup was being adjusted.

TODO picture of wedge

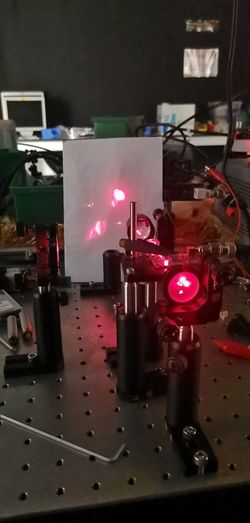

Fortunately, the holes in the board are, by coincidence, mostly aligned with the holes in the mount. Although the mount uses imperial-sized screws, we were able to find the screws and components necessary to fix the board in place securely, producing the rather ugly assemblage pictured below.

TODO insert picture

We also elected to place the board on a mount permitting the pitch and roll of the board to be adjusted, because it is difficult to guarantee its alignment otherwise, and since the crystal is birefringent, we want to ensure it is aligned with the polarisation of the laser, so that the whole beam will experience the same phase difference, and the fringe visibility can be maximised.

Lens and Photodiode Alignment

Results & Discussion

Equipment Parameters

We are using a Hamamatsu S5106 Si PIN photodiode as our detector, with a resistive load of Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle 1~\mathrm{M\Omega}} . Measurements are taken with a Kenwood CS-5270 oscilloscope with Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle \Delta f = 100~\mathrm{MHz}} .

Fringe Formation

TODO talk about different shapes of fringes, pattern formed on screen, etc.

Voltage Readings

TODO talk about change in voltage observed with and without the laser and as the phase is changed, estimate power being received using voltage and resistance, estimate the various sources of noise.

Phase Modulation

Despite our best efforts, we were not able to perfectly align the EOM board. The Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle \ce{LiNbO3}} crystal's optical surfaces seem to be somewhat reflective, producing an additional red spot on the screen. The spot was confirmed to be produced by the crystal by blocking the two mirrors and observing that the spot is still there, whereas it disappears if light from Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle B_1} is not allowed to reach the crystal. If the setup was perfectly aligned, this additional spot would have formed exactly at the position of the beam that reflected from Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle M_1} , but this was not the case. While this additional spot is not visible in the image, a similar effect produces the additional misaligned spot on Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle M_1} , this time caused by the beam, reflected by Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle M_1} , hitting the crystal. While some light is transmitted onwards to the screen, some is reflected, forming the additional spot on Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle M_1} .

While the additional spot sometimes displays visible fringes, it does not interfere with the beam from Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle M_2} when said beam is overlapped onto it. That the fringes arise from interference can be verified by applying a slight pressure to the EOM board, which produces a shift in the pattern characteristic of interference. This tells us that the path difference between this path reflecting from the EOM, and the path reflecting from Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle M_2} , exceeds the coherence length of the laser. However, it is unclear what this reflected beam is interfering with. TODO