Custom atomic beam source

Team Members

Lu Tiangao, Li Putian

Introduction

In this report, we introduced an atomic oven designed by ourselves. The whole design will be suitable for atoms that need temperature ranging from 500K to 1300K. The idea came from our lab's commercial atomic beam source was both expensive and having some defects. Although our effusion cell bought from Createc works very good now. But the SVT one got leak before and we found the leak reason, then came to the design idea of our project of custom atomic beam source.

Theory part

Vapor Pressure

Indium is the group III atom, and it has two stable isotopes In-113 and In-115, the atom we use is In-115 with an abundance of 95.7%, the melting point is 156.6°C. To calculate the density of atoms coming from the nozzles. We should know the pressure and temperature of the gas, which the density formula is given by:

When a material is in thermodynamic equilibrium with its vapor at a given temperature in a closed system, the pressure at this time is called vapor pressure. The vapor pressure of indium is given by

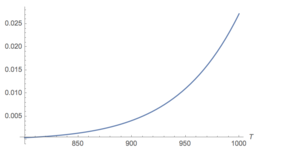

We can plot the vapor pressure with Temperature range from 800°C to 1000°C:

A pressure of 1e-3 torr is a number typically used in many cold atom experiments. Thus we get the temperature around 833.82°C is the suitable temperature of indium atom experiment. Then, according to the density formula, we can get the density of atoms inside the crucible is

Maxwell distribution

Firstly, indium atoms inside the crucible will obey the Maxwell-Boltzmann distribution.

However, when considering the speed distribution of the atoms coming out of the nozzle, we should add another factor of v into the distribution function. Because the gas atoms emerging outside of the small apertures cannot be representative of the atoms inside the crucible. So the distribution function of the outside atoms is given by:

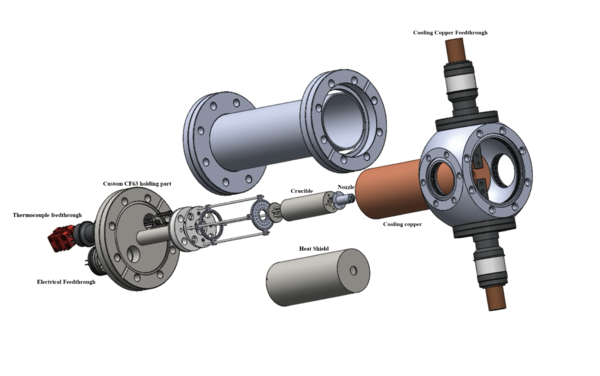

Custom oven design

The whole oven consists of heating parts, temperature testing and control parts, supporting elements and cooling parts. Also, the core part of crucible and nozzle. Here is an exploding view from our indium oven.

Items needed

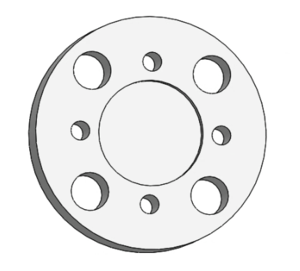

- Custom Flange feedthrough

- Thermocouples and thermocouple feedthrough

- Tantalum heating wires and current feedthrough

- Crucible and nozzle

- Tantalum wire holding rings

- Vacuum Flange, cube and viewports

- Heating wire power system

- Cooling system for oven

Crucible and Nozzle design ideas

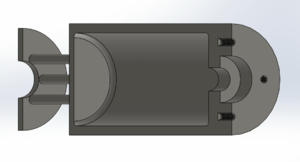

The core part of an oven is the crucible which stores the indium. The crucible design idea comes from the reason that the SVT cell leaked. The most possible explanation for the leak is that when the indium inside the crucible was heating or cooling through the phase point, its volume will becomes bigger which will extrude the gasket which linked the crucible and its sealing ring. Therefore, we will design the crucible which firstly can contain enough pure indium and the indium liquid should be under the center nozzle position. Our design will not have the leak problem any more, because the crucible has a 5mm hole in the middle. Indium metals will be all under the lower edge of the hole. The 5 mm hole has two use: one is for loading the pure indium small ball into the crucible, the other is to plug a micro-array nozzle. But the nozzle with 5mm diameter will be too small, it should be at least 1cm. The tricky thought with the crucible front panel design was drilled the front of the crucible with 5mm depth, 10mm width hole firstly, and then, drilled 5mm width hole. Then we can plug in the 1cm nozzle! The crucible will be made with stainless 316L. To determine the size of crucible, we should know how much indium we need. We need 35g indium. Calculate the volume we need Because we decided the whole oven can be fitted in a CF63 nipple and linked the nipple to the cube which will be connected with ion gauge, ion pump. So the crucible width will be small, the width of it is 12mm and length of the crucible is 7cm. The crucible will use a 316L stainless steel because that it is cheap and easy machinable. Also, it has high melting point of 1390°C which is much higher than the working temperature for our design. The mean thermal expansion coefficient from 20-1000 °C is cm/(cm°C) , which we can accept. Here is the image of the crucible design.

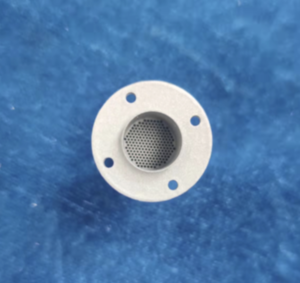

The nozzle width is 10mm, with length of 22mm, on one side of it should be plugged inside the crucible. There are 203 micro channel arrays with length of 1cm that designed to make the atom beam collimated.

The nozzle should work at much higher temperature (50°C higher) than the crucible to prevent the nozzle from clogging. We choose the 316L stainless steel for the fabrication of the nozzle, which is the same with the crucible to keep same thermal expansion rate when they are heated.

Heating elements

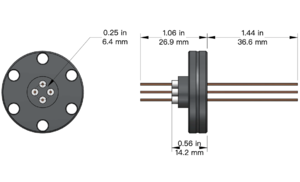

The crucible will be heated up in vacuum condition, so the method here is to use radiation heating method by heating wires. The heating wire we choose is tantalum wire which can easily reach a high temperature of 1500 degree or more. We use the type of Temper annealed PM Sintered (Powder metallurgy Sintered wires) which means that the starting material is in powder form and typically have a higher UTS (ultimate Tensile Strength). To connect the heating wire inside the vaccum and outside power supply, we need power feedthrough (Kurt J.Lesker EFT0043032).

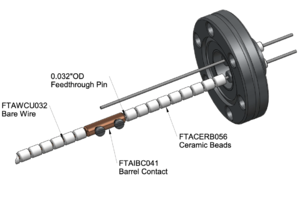

There is an connection example of linking the tantalum wire with the power feedthrough:

We also bought the ceramic beads (FTACERB056) to help isolate and avoid short-circuiting the heating wires and inline barrel connector to connect the feedthrough with the tantalum wires (FTAIBC041) from Lesker. For the test setup, I only go through the easiest way of connecting the cu wire outside vacuum with the bench power supply directly by the banana connectors.

temperature test parts

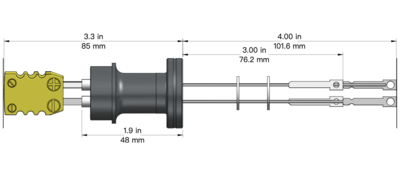

We have to use thermocouple to get the temperature of the crucible and the nozzle area. For the temperature needed will not exceed 1000°C, so we can use type K thermocouple whose accessories are common in the market.

Holding parts

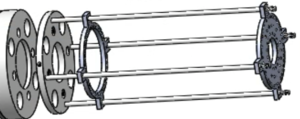

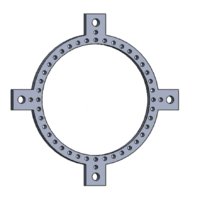

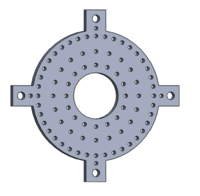

To hold the heating wires and thermocouple hot junction, I designed the supporting parts. The skeleton of it looks like this:

There are two kinds of macor baseplate which are used for the wires to penetrate through. We use macor ceramic materials because it is extremely machinable, and offers tight-tolerance capabilities, allowing complicated shape design (optimal performances up to ±0.013 mm for dimensions, < 0.5 μm for finished surface and up to 0.013 μm for polished surface). Macor remains continuously stable at 800 °C, with a maximum peak at 1000 °C under no load, and doesn’t creep or deform. Its coefficient of thermal expansion readily matches most metals and sealing glasses.

And they are mounted onto the 316L stainless steel baseplate which has four M2 threaded supportig rods to penetrate the macor's holes. And the macor baseplates are fixed by M2 nuts (bought from UC components). There are four M1.6 threaded holes on the edge of the stainless steel baseplate.

I also add a heat insulation part between the stainless steel baseplate with the Lesker custom feedthrough which will be described soon. It is also fabricated in macor material, for macor has a thermal conductivity of 1.46 W/(m·K) which is very small enough to be used as heat insulation material. We have four big holes which leave for the two thermocouple hot junctions to go through and in the center of the macor insulation part, there is an offset from the surface, and at that position, the crucible can be put on.

We now come to how to connect the holding parts together. There are four M4 threaded holes in the stainless steel baseplate, macor thermal insulate part and vacuum flange feedthrough, we can easily use vented screws (which are good for vacuum) to connect them together. The vented screws are also bought from UC components.

Cooling parts for the oven

I designed a 316L stainless steel shield which is polished both inside and outside. It was connected with the stainless steel baseplate which we mentioned before by M1.6 vented screws. The shield is used for reflecting heat radiation from the heating wire onto the crucible. This idea comes from Etienne Staub's master thesis.

In the createc oven, we use water cooling method, however, the chiller is noisy and sometimes caused problem when the electricity shut down. So in this design, we will use another method. Outside the stainless steel shield, I designed a copper shield with the same shape. By linking two big copper power feedthrough with the copper shield, we can cool the oven by connecting thermoelectric cooler (TEC) with the copper feedthrough.

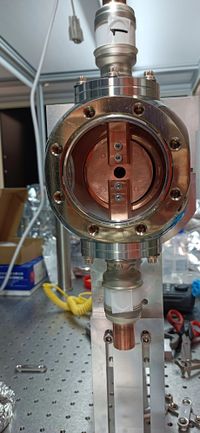

Oven setup

Wiring practice

The wiring part is the most difficult job in this project cause it need a lot of practice and patient.

Washing parts for vacuum

- We began by filling the large ultrasonic bath in the wet lab with 6x800 mL of tap water and 200 mL of Decon 90 detergent. The bath was heated to 50 C. Keep the washed stuff in the bath for 20 minutes and above.

- Next we rinsed each part with distilled water and then blew them off (for drying purposes) with the air gun in the wet lab.

- Then each part was rinsed in alcohols. The order was acetone, isopropanol, and methanol. We focused on cleaning the insides and knife edges of each part. The alcohol rinse was done by fashioning a hook to hold up each vacuum part through one of its clearance holes, and then we sprayed the solvents into each part held up by the hook.

- After the solvent rinse, we dried each part by blowing it with the air gun in the wet lab.

Oven setting up

Vacuum bake

Because the tantalum wire cannot be heated with oxygen environment, so we need an UHV vacuum environment(we need a 1e-9 torr) to heat the tantalum wire up which will further radiate heating the crucible and nozzle. However the pump station can only provide a vacuum with 1e-7 level without baking the vacuum system. Therefore, we began our baking for the custom beam source. By wrapping heating wires at the oven, adding four thermocouples to test the temperature, and wrapping aluminium foils to heat insulate.

When heating up the heating wires, we also prepare a monitor system to view the temperature around the baking area and pressure inside the oven. Our desired temperature for baking is around 240 celcius with the variac voltage of 173V.

Problem we met

At the first attempt of baking, we found a leakage of the vacuum because we saw the vapour pressure at the pump station gauge increase to 1e-4 level. That means there was a serious leakage of this system. We went through the leak check by following ways:

- tighten the srews

- replacing some possible leaking parts by blank

- spray the leaked part with methanol to find approximate location of leakage

- use vacseal to heal the leak point and find the exact leaking point

Next step

Since the unexpected leaking of the custom flange feedthrough, there was a bit delay for our plan. The bake for the oven need 1-2 weeks, after the bake, we will heat up the tantalum wires by two 10V, 36A bench power supply and test the vacuum and cooling parts. There are few things we want to check later:

- whether the crucible will arrive 900 celcius

- how is the vacuum inside the oven

- without cooling the copper feedthrough, how is the temperature of it and pressure inside.

- with cooling the copper feedthrough, how is the temperature of it and pressure inside.

- indium inside crucible come out or not

Conclusion

We presented the details of a custom design and setup of an atomic beam source which can work from 300K to 1300K. Through this project, we nearly fully handle the vacuum system technology and 3D design and material selection knowledge. The design showed here is much cheaper than the commercial ones, and will have better properties.

Reference

- A. Nesmeyanov. Vapor pressure of the chemical elements. Elsevier Publishing Company, Amsterdam,1963.

- Stephen J. Blundell and Katherine M. Blundell. Concepts in Thermal Physics.

- Wikipedia. Macor. https://en.wikipedia.org/wiki/Macor.

- Etienne Staub. Developing a high-flux atomic beam source for experiments with ultracold strontium quantum gases. https://ultracold.sr/publications/thesis_etienne_staub.pdf.