Electron Gun

Electron guns have been used since the late 1940s in cathode ray tube (CRT) televisions and monitors.

The design of our electron gun project can be understood through its two separate functions: electron emission and electron acceleration. In summary, to introduce electrons into the system and then to accelerate these electrons in a controlled manner towards a target.

The introduction of electrons is done through thermionic emission. An electric current is passed through a filament which will undergo Joule heating. Thermionic emission will take place once the filament is sufficiently heated, hence introducing the electrons into the system.

The acceleration of electrons is achieved by differentially biasing electrodes within the electron gun to create an electric field that will accelerate the electrons towards the target in a controlled manner. The last clause requires more than mere potential differences but electrostatic lenses such that the electron beam can be coaxed into a desired trajectory.

Broadly, both these objectives would be achieved by having an acceleration section, followed by a focusing section.

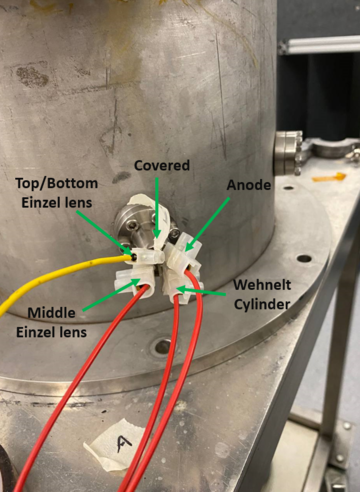

Directly following thermionic emission, the electrons are subject to an accelerating potential. This accelerating potential is provided by an electrode (anode) which is held at a positive potential difference with respect to the filament. This causes electrons emitted from the filament to be accelerated towards the plate. Working in tandem with the anode is the Wenhelt Cylinder. Once accelerated past the anode, the beam is again once more with an Einzel lens.

These two loosely defined steps should result in an electron beam that is focused on a target. The target could be anything from a screen coated in phosphorous (to show the beam spot), to a Faraday Cup which is connected to a current measurement device.

Team Members

The group consists of 4 team members, listed below in alphabetical order.

- Aliki Sofia Rotelli (A0236272H)

- Lai Tian Hao (A0236351L)

- Lim En Liang, Irvin (A0173028J)

- Tan Chuan Jie (A0154805E)

Idea

The project is divided into two parts.

Electron source

An electron source would be fabricated with the use of a Lenard/Crookes tube. This tube is an electrical experimental discharge tube within a vacuum system that generates electrons by ionisation of the remaining air molecules within the chamber. The project would hence be built in a vacuum chamber.

Collimated beam

The generated electrons would need to be collimated into a beam with the use of a homemade magnetic lens (a solenoid of some form). To observe this beam, a material capable of showing the electron spot would hence be needed in our project.

Concepts

Focusing Lens

Beam Resolution

One of the most important considerations in the scaling down portion is the Rayleigh Criterion. The Rayleigh Criterion relates the critical dimension (CD), or smallest feasible feature size resolvable by an optical system, to the imaging wavelength () and numerical aperture (NA). This criteria is crucial as a result of a small CD, as shown in the equations below.

In the above equations, θ is the maximum half-angle of the light cone that enters or exits the lens, n is the refractive index of the medium, λ is the wavelength of light.

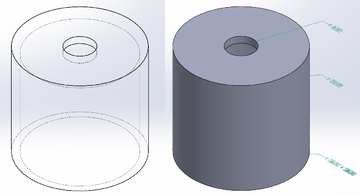

Wehnelt Cylinder

The Wehnelt cylinder is a negatively biased cylinder located right after the electron source. It affects the focusing of the electron beam and the electron emission from the source. When tuned appropriately, the Wehnelt cylinder, together with the anode, aids in the emission of electrons from the source by creating a net electric field from the attractive anode and repulsive Wehnelt cylinder. Being negatively biased, the Wehnelt cylinder also acts as a convergent electrostatic lens which focuses the electron beam path from the filament to the anode.

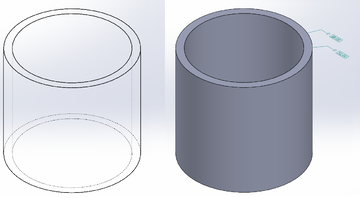

Einzel Lens

Similar to the Wehnelt cylinder, the Einzel lens is also an electrostatic lens. In this project, the Einzel lens would be made of three cylindrical tubes in series along the direction of the electron beam.

Due to the electrostatic symmetry, the ions do not lose energy through the focusing process. In operation, only the middle Einzel lens is actively biased (positively). The other components of the lens are held at ground potential.

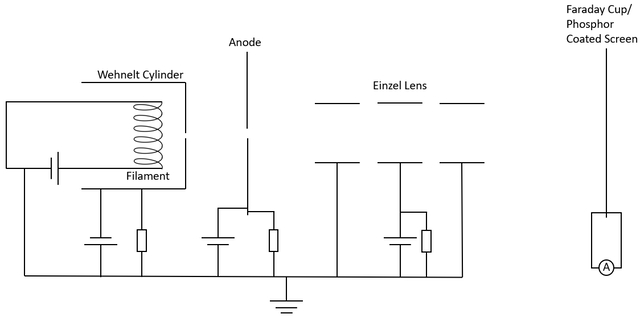

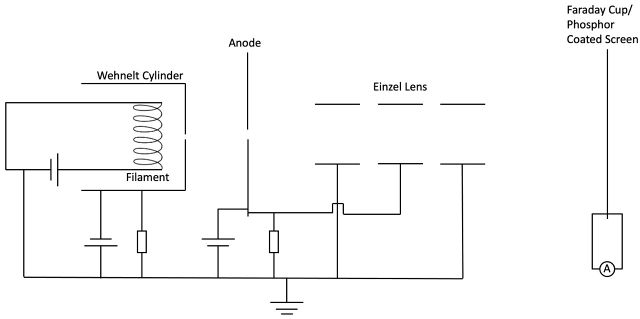

Schematic of Electron gun

The electrical schematic is concerned with controlling the potentials of critical components. These components are the Wenhelt cylinder, Anode, and Einzel lens. A separate distinction would be the polarity of these components. Both the Anode and Einzel lens would be positively biased up to 1 kV above ground while the Wenhelt Cylinder will be negatively biased down to 1 kV below ground (i.e. -1 kV). These values are simply ranges and specific potential values were determined through simulations. The components would be biased to recreate the conditions in the simulations.

Each of these potentials would be achieved with separate high voltage Power Supply Units (PSUs). Due to the shortage of devices, only 2 PSUs were used. This was achieved by biasing both the Anode and Einzel lens to the same potentials, thus allowing one PSU to be used for both. The simulations suggested that this configuration would provide sufficient acceleration and focusing effects on the electron beam.

The actual practical set-up is more accurately depicted in the schematics below.

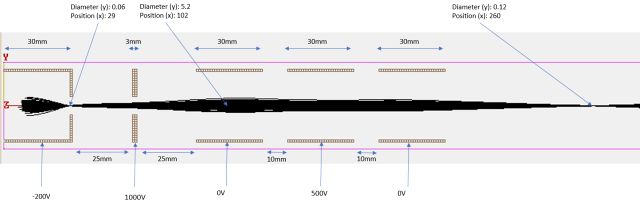

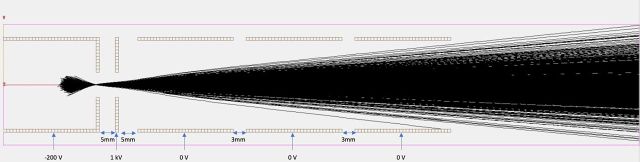

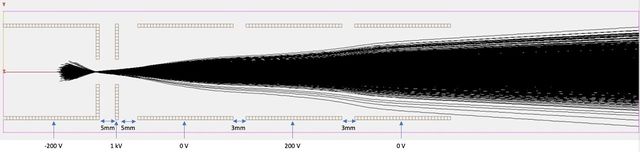

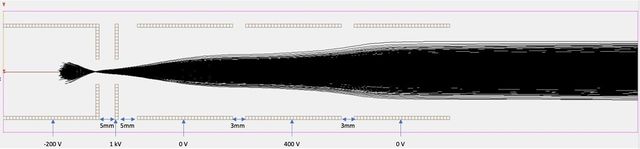

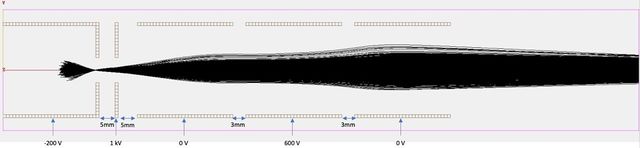

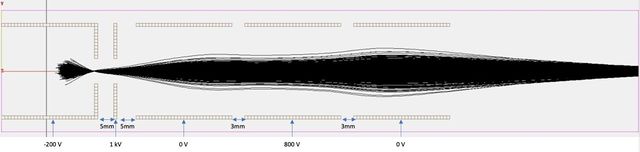

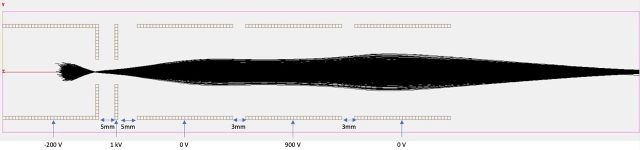

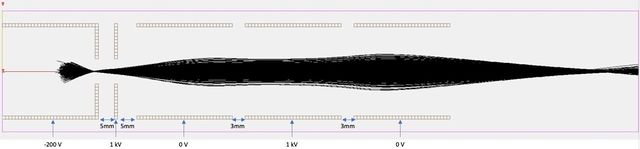

Simulated Proof of Concept

Simulations were performed in a simulation software, SIMION, based on the above-mentioned proposed configuration.

| Wehnelt | -200 V |

| Anode | 1000 V |

| Middle Einzel | 500 V |

The above shows an ideal situation. However, in practical set-ups, the space is constrained and all the items had to be placed closer to each other. This results in the set-ups depicted below, with all simulations at top-down cross-sectional view.

As shown, even with the compacting of the electron gun, a focused beam spot is still able to be produced with the following parameters.

| Item | Original | Revised |

|---|---|---|

| Wehnelt | -200 V | -200 V |

| Anode | 1000 V | 1000 V |

| Middle Einzel | 500 V | 900-1000 V |

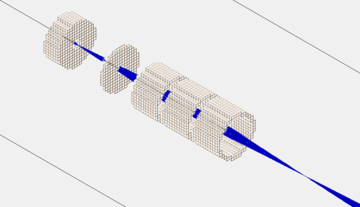

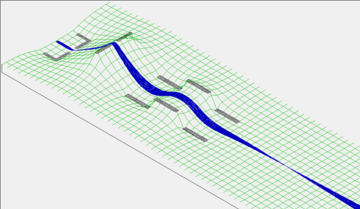

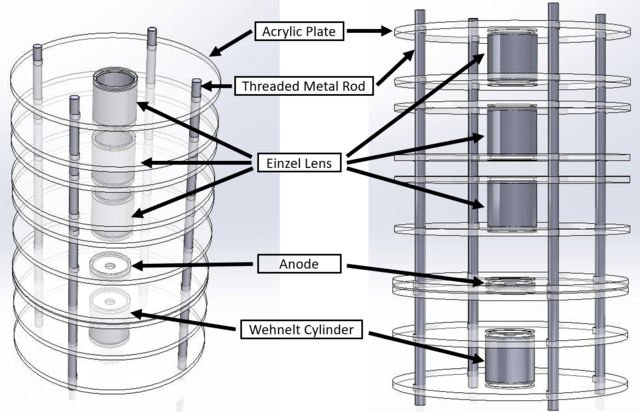

Design of the electron gun's "central column"

Based on the schematic of the simulation, the development of a "central column" was designed using a 3D Computer-Aided Design (CAD) software, SOLIDWORKS. It consists of 4 main components as described below.

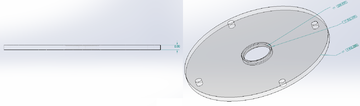

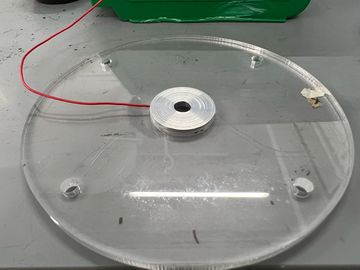

Acrylic Plate

The acrylic plate was created in a disk shape with a 100 mm outer diameter and a 28 mm inner diameter. In addition, the disk's inner ring features a 1 mm depth with 32 mm diameter recessed on both sides. The recess was created to allow for the secure installation of subsequent elements.

Einzel Lens

The three components of the Einzel was designed with dimensions:

- Outer diameter: 32 mm

- Inner diameter: 28 mm

- Length: 30 mm

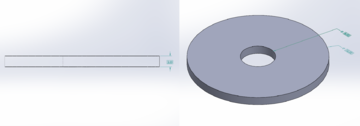

Anode

The anode was designed with dimensions:

- Outer diameter: 32 mm

- Aperture (diameter): 8 mm

- Thickness: 2 mm

Wehnelt Cylinder

The Wehnelt cylinder was designed with dimensions:

- Outer diameter: 32 mm

- Inner diameter: 28 mm

- Aperture (diameter): 8 mm

- Length: 30 mm

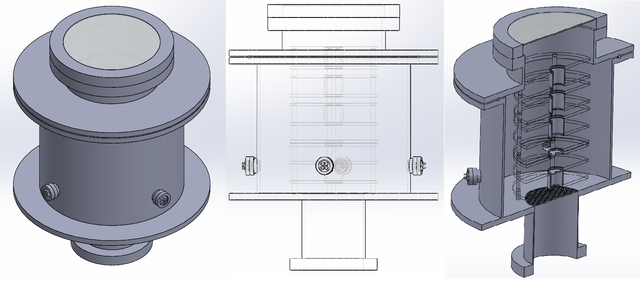

"Central Column" design

"Central Column" with Chamber design

Equipment & Components

To build the electron gun, the following items were considered for the system.

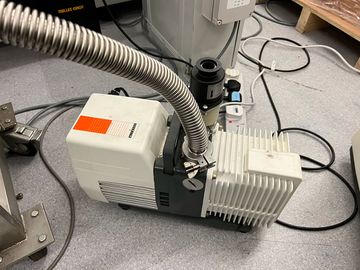

High Vacuum (HV) Components

- Roughing Pump (RP)

- Turbo-Molecular Pump (TMP)

Electrical Components

- 2 x PHYWE High voltage power supply with digital display (10 kV DC, 2 mA)

- Current Controlled PSU

Beam Focusing Components

- Einzel Lens

Measurement Components

- High Vacuum Digital Gauge, with range ~ mbars

- Edwards PRM10 (Pirani Gauge)

- Edwards D145-41-000 (Penning Gauge)

Other Components

- Filament (Possible choices)

- Tungsten (W) (Used in our system)

- Lanthanum Hexaboride (LaB6)

- Cerium Hexaboride (CeB6)

- Phosphors

- Zinc sulfide(ZnS) (Copper/Silver Activated)

- CF-40 Copper Gaskets

Main Set-Up

Central Column

All of the items listed below were made in the CQT workshop located in S15 level 1.

Acrylic Plate

The laser cutter was unable to make cuts at varying heights. To work around this limitation, a different approach was devised.

First, a disk was cut out of a 5 mm thick acrylic sheet with an outer radius of 100 mm and an inner diameter of 32 mm. Next, a 32 mm/28 mm (outer/inner) diameter ring was cut. Finally, the pieces were put together with an adhesive compound that allowed for a 1 mm recess on both sides of the disk.

9 additional disks were manufactured in the same manner to obtain a total of 10 disk plates.

Einzel Lens, Anode, Wehnelt Cylinder

The Einzel lens, Anode, and Wehnelt cylinders were sculpted out from a single aluminum rod with a length of 350 mm and a diameter of 42 mm. A lathe (a machine that rotates a workpiece about an axis of rotation to perform an operation such as cutting, sanding, drilling, etc.) was used for the fabrication of these 3 components.

Upon clamping down the aluminum rod securely, the rotational gears were set to "low" with a rotational speed of 105 and 610 rounds per minute (RPM), with a large and small drill bit respectively. The drill bit was secured within the "tail stock".

After achieving the structure's inner diameter, a "facing" tool was used to remove the surface material from the outside construction, "thinning" it from 42 mm to 32 mm. Rotational gear speed was set to 610 RPM when "facing".

Electron Source

The electron source, a filament, was also prepared by breaking a bulb. The glass was broken by lightly tapping the bulb with a metal hammer in a plastic bag. Broken glass fragments were then cleaned up.

Photos

The 3 components and the filament were successfully prepared for the system.

Chamber Preparation

To prepare the chamber, latex gloves were worn to prevent contamination due to natural oil and minerals on the skin. Any contamination would result in low vacuum performance.

Electron Source

M5 nuts were utilized as a locking mechanism to ensure that the acrylic plates were firmly secured in place. The nuts were inserted both above and below the plates.

Wehnelt Cylinder

The Wehnelt cylinder was carefully lowered into the chamber. Care has been taken to ensure that it does not touch the filament.

Other Components

The rest of the components (Anode and 3 Einzel lenses) were assembled fully within the chamber to achieve a full stack that is similar to the illustration of the schematic diagram.

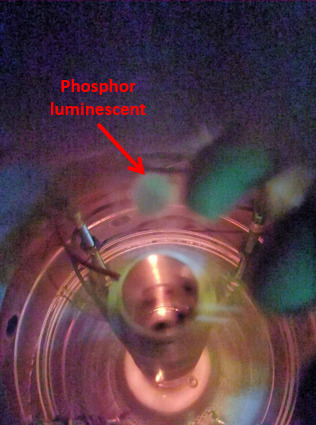

Phosphor Screen

With the central column completed, the phosphor (spread on a 1" by 2" cover slide) was mounted on the chamber lid with the use of Kapton tape.

During the process of mounting, the cover slide shattered, causing a slight misalignment of the phosphor with respect to the center of the column.

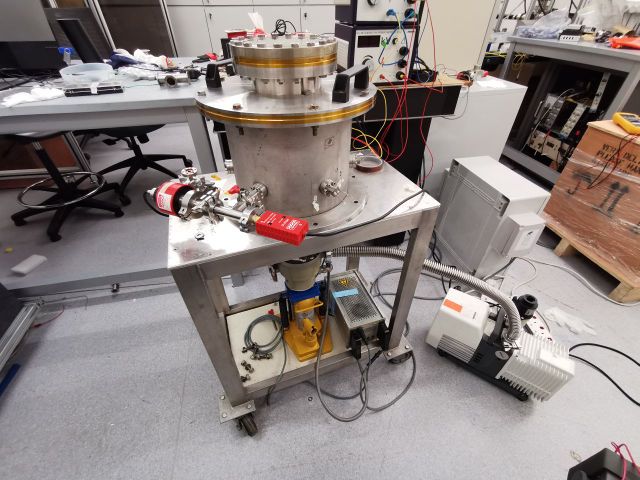

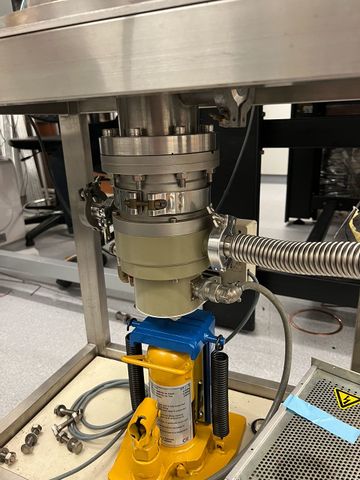

Fully Assembled System

The system was fully assembled with the RP and TMP installed with a gauge reading the chamber pressure. The PHYWE PSUs were also attached through the external feed-throughs.

Measurements and Tests

Conductance Test

A conductance test of individual components were performed during to ensure proper connections between the components and the feedthroughs.

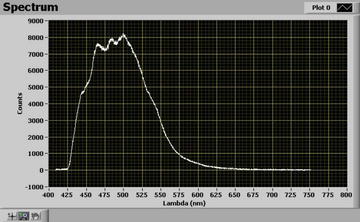

Phosphor Characterization

The phosphor powder used in this project was kindly provided by Nejilock. It has a composition of >99% Zinc Sulfide. The powder can be characterised using a fluorescent microscope.

The powder was excited with UV light and the emission was collected. The spectrum of wavelengths emitted is presented in the figure below. The majority of the emission is in the 450-550 nm region, meaning the powder will have a blue/green glow.

Several methods to insert the phosphor powder into the system were attempted. The most successful method was to create a paste consisting of a mixture of transparent nail polish. This paste was then added to the powder that was already applied on a small section of the glass slide. Once the thinner evaporates, the powder will be stuck to the glass.

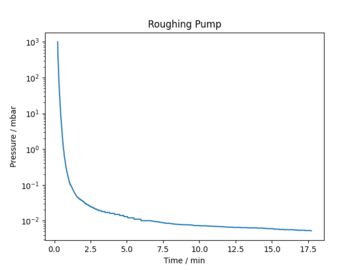

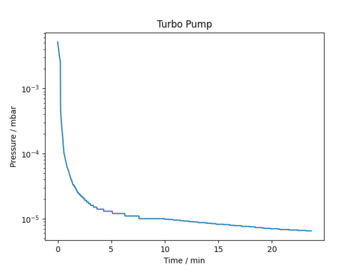

Pressure Characterisation

The Roughing Pump (RP) and the Turbomolecular Pump (TMP) were both characterised.

For a turbo-roughing system, a vacuum pressure of approximately mbar must first be achieved using the RP before the TMP can be turned on, so as to not damage the turbine blades of the TMP.

Various pressures at different timings are recorded into the table below.

| Time | Pressure |

|---|---|

| 41 min | mbar |

| 16 h | mbar |

| 48 h | mbar |

The graphs of pressure against time for both RP and TMP were also plotted into logarithmic graphs, as shown below. The RP was transitioned into the TMP at approximately the 1064th second at a pressure of mbar.

Experiment and Results

The experiment was conducted after pumping down the chamber for several hours in a dark environment. Care was taken such that the 1000 V PSU was provided with ample safety precautions.

The final parameters were tuned with similar simulation parameters.

| Wehnelt | -200 V |

| Anode | 1000 V |

| Middle Einzel | 1000 V |

As mentioned, because of the identical potential for the Anode and Einzel lens, the same power supply was able to be used for both of them while a separate one was used for the Wehnelt cylinder.

The filament power supply was set to 10 V DC. Current provided was 0.1104 A as shown on the filament PSU (Keithley 2200 DC Power Supply).

A tinge of fluorescence can be spotted which is illuminated from the phosphor coating with a more prominent glow located at the top right quadrant. This coincides with the slight misalignment of the glass slides during installation.

Due to the low intensity of the fluorescence, no useful data could be taken. The discussion is included in the section below.

Problems and Discussions

Throughout the project, various obstacles were met. Methods to overcome them were attempted but not successful.

Dim luminescence of phosphor

When the set-up was running, the glow of the phosphor was barely observed. This could be attributed to the thickness of the phosphorus and the spot size.

As mentioned previously, the spot size of the beam would be a few hundred microns. With such a spot size and a thick phosphorus layer, when the beam hits the bottom of the layer, it would illuminate only slightly at the top layer. The phosphor would thus only appear to slightly "glow" and not allowing us to see the spot as expected. To counter this, a thinner layer of phosphor could be fabricated.

A Faraday Cup was initially planned to be included for current measurement, but due to logistical issues, we could not get the picoammeter (RBD 9103) that was indented for the project on time.

Another reason for the low luminescence could be due to a low vacuum. With all components installed, the pressure was relatively higher ( mbar) than what was characterised above. One way to overcome this is to clean all components thoroughly again (sandblasting, chemical cleaning, etc.). Unfortunately, it could not be done on time for the module.

Filament alignment

As the set-up was built from the bottom-up and due to limitations of the size and the holder, the filament could not be adjusted freely, thereby resulting in possibilities of misaligning the filament.

After the set-up was complete, it was observed that the filament was biased to one side. This affects the results as the simulation assumes the filament to be at the centre of the Wehnelt cylinder.

A future improvement would be to mount the bulb base on a stage with some degrees of freedom. However, this would likely add some height to the base plate, resulting in a need to compact the system further.

High Voltage PSUs

In the current set-up, only 2 PSUs were used to vary the potential differences of the 3 Einzel lenses and the Wehnelt cylinder. An extra power supply would enable the Einzel lens potential differences to be tuned separately, providing better fine-tuning abilities.

Logistics

The project was originally planned to be located in the Physics Acoustic Room (S13 level 1). However, during the course of designing the chamber, the location was shifted to a lab within the Centre of Ion Beam Applications (CIBA), at S7 level 1 as the tools were more readily available there.

The chamber design was revised intensively before the current version was reached. The original design had to be scrapped due to a lack of components.

Future

As the project has caught the attention of another Professor, it will be continued after PC5209 officially ends for the current semester.

Conclusion

The electron beam was observed, but limitations meant that we could not measure the beam spot size nor other parameters.

Further attempts and modifications will be planned such that the electron gun will be working for the purpose of other projects that requires it, such as a compact electron imaging system.