Kerr Microscope: Difference between revisions

| Line 6: | Line 6: | ||

* Joel Yeo | * Joel Yeo | ||

* Gan Jun Herng | * Gan Jun Herng | ||

* Sim May Inn | |||

(Feel free to edit this page or email me at joelyeo@u.nus.edu if you would like to join.) | (Feel free to edit this page or email me at joelyeo@u.nus.edu if you would like to join.) | ||

Revision as of 08:22, 22 March 2022

Imaging a sample can be done in many ways, depending on the light-matter interaction we are interested in observing. The magneto-optic Kerr effect describes the change in polarization and intensity of incident light when it impinges on the surface of a magnetic material. The resultant reflected light can then form an image through focusing optics which provides high contrast between areas of different magnetization.

Through Kerr microscopy, we aim to characterize the relative changes in magnetization across a magnetic sample.

Team members

- Joel Yeo

- Gan Jun Herng

- Sim May Inn

(Feel free to edit this page or email me at joelyeo@u.nus.edu if you would like to join.)

Idea

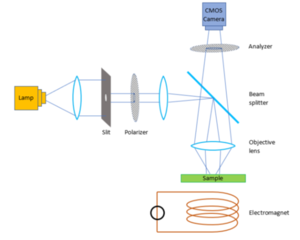

In this project, we will be aiming to build a basic Kerr microscope using off-the-shelf polarizers, objectives, detectors and laser source. A magnetic sample can be borrowed from a team member's research lab. To increase the field of view, we also plan to incorporate automatic raster scanning of the sample through means of an Arduino-controlled sample stage.

Some useful search keywords are:

- Faraday rotation

Setup

Location: S11-02-04

Theory

Light reflected from a magnetized surface may change both polarization and reflected intensity. This comes about because the magneto-optic material has an anisotropic permittivity, meaning that it depends on the direction. The permittivity affects speed of light in a material.

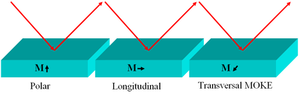

The magneto-optic Kerr effect (MOKE) describes the changes to light reflected from a magnetized surface. MOKE can be further MOKE can be further categorized depending on the relative orientations of the reflecting plane to the magnetic field.

Experiments involving the different MOKE orientations are typically carried out in the following manner.

- Polar MOKE -- Near normal incidence to avoid Kerr rotation (what's this?).

- Longitudinal MOKE -- Incidence at an angle to surface, parallel to field. Linearly polarized light becomes elliptically polarized. The change in polarization is directly proportional to .

- Transverse MOKE -- Incidence at an angle to surface, perpendicular to field. This affects reflectivity . Viewed from the source, if points to the right of the incident plane, the Kerr vector adds to the Fresnel amplitude vector and the intensity of the reflected light is . If it points to the left, it is .

Lab Session Logs

10 Feb 2022

Hunted down the required parts. We used the diagram from NaBiS from Politechnico di Milano’s physics department as our guide [1].

Linear polarizer was found, but extremely dirty. First rinsed with water than finished cleaning with isopropanol (IPA). IPA available in S11-02-04 room cupboard. Discussed some other things between us and with TAs:

- Stage requires mm precision

- blah

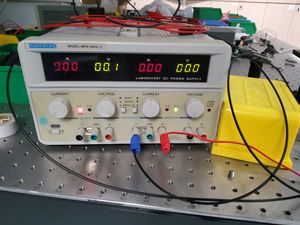

We only used the two knobs on the right hand side. First turn the voltage up slightly to set a limiting voltage, then slowly turn on the current till the LED turns on. Observation shows LED tends to turn on at about 2V. The positive end (red) should be connected to the positive (anode) side of the LED. This can be seen as the longer leg of the LED.

15 Feb 2022

From the info on the NaBiS page, we may need to characterise the material in all three MOKE orientations to get a full 3D image. But we’ll think about that later.

Today was more parts gathering, a little machining to make the parts that we need.

Magnetic material - Got a bunch of steel sheets from CK, and some copper wire to wrap around it like a mini solenoid. The sheets are a soft magnetic material ( = 5000 − 7000 according to CK) and will be magnetised when a current runs through. CK suggested we set it up so we can change the direction of the magnetic field by switching ??? (not exactly sure, will need to figure out later), and not manually moving the sample. Might be easier down the road.

The steel sheet was cut with some steel cutting scissors, and de-burred with sandpaper. The copper wires had to be stripped for connection. This was done with some Stanley blades and polished with some sandpaper. Not the cleanest, but as long as we get a current it’s fine.

18 Mar 2022

Field of view provided by the webcam was too wide in comparison to the laser spot. Ideally, the image should be less than the diameter of the laser spot. A few methods were proposed in response to this:

- If we were unable to see the actual area, we should minimally be able to see a change in intensity of the imaged spot, with and without a magnetic sample. However, we were not able to observe such variation in intensity, probably due to the small size of the area of interest, and the weak signals we were receiving.

- Attempted to block out all ambient light, and isolate only the signals from the laser spot, but again, we were not able to observe any obvious variation in intensity.

- Propose the use of a beam expander before the camera - was not implemented yet.

- Remove the blue LED about the camera which was initially there for simply aesthetics. Soldering was utilised to remove the relevant circuits and parts from the board.

- Removed the lens in the camera, which causes the wide view.

Next: to test if LED and lens removal helped ease the situation.